Overview

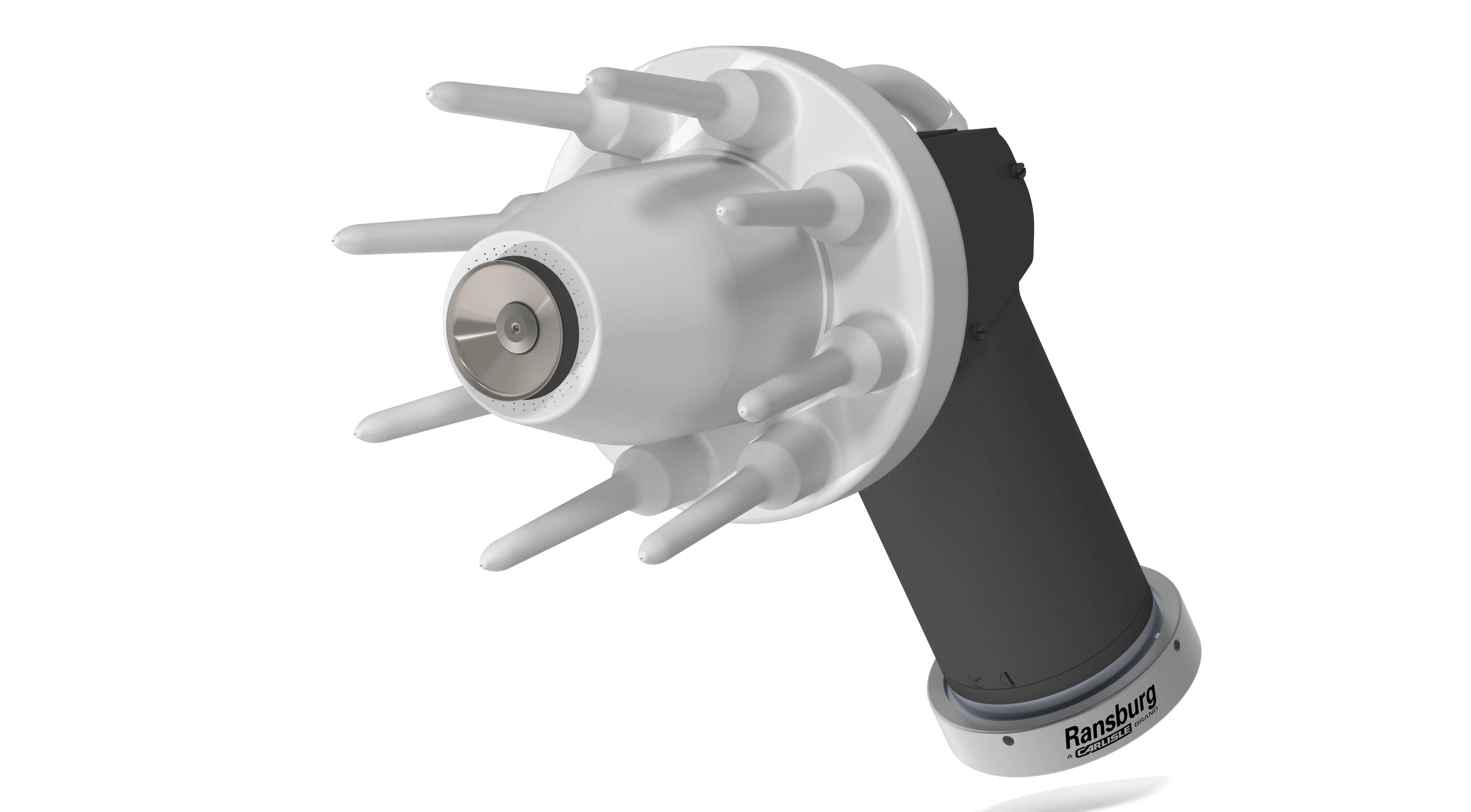

The RMA-600 Series is Ransburg’s next generation of robot mounted rotary atomizers focused on delivering improved spray pattern control, cleanliness during operation, and longer lasting components. This series of applicators can be used across a wide range of solvent and water borne coating materials. With the capability to operate with or without electrostatics utilizing direct and indirect change technology.

Our engineering team set out to minimize or eliminate “ghost patterns” that occur from excess paint not staying contained within the desired spray pattern. By minimizing or eliminating this excess paint, customers can experience greater transfer efficiency and cleaner applicators. The applicators new turbine is capable of speeds up to 100,000 rpm’s and can last over 2-3 times longer than previous model turbines.

FEATURES

Optimized Dual-Shaping Air

- Larger range of spray patterns

- Improved cleanliness

- Increased transfer efficiency

Improved Production Uptime

- Dual Purge capabilities reduces color change time

- New fluid nozzle design reduces solvent usage and cleaning time

- Quick disconnect tubing bundle removes applicator in less than two minutes

More Robust Components

- Longer turbine life

- New single-piece splash plate design

- Redesigned tubing bundle and cable connections

RMA 600 Series…..helping manufacturers finish first

Literature

-

RMA-660 Sales Literature 05-319-01

-

RMA-670 Sales Literature 05-320-01

-

RMA-680 Sales Literature 05-321-01

-

RMA-660 Robot Atomizer Service Manual

-

RMA-670 Robot Atomizers Service Manual

-

RMA-680 Robot Atomizers Service Manual

-

Turbine Rebuild Procedure SI-21-06

-

Cascade Assembly Service Instruction SI-22-02

Overview

The RMA-600 Series is Ransburg’s next generation of robot mounted rotary atomizers focused on delivering improved spray pattern control, cleanliness during operation, and longer lasting components. This series of applicators can be used across a wide range of solvent and water borne coating materials. With the capability to operate with or without electrostatics utilizing direct and indirect change technology.

Our engineering team set out to minimize or eliminate “ghost patterns” that occur from excess paint not staying contained within the desired spray pattern. By minimizing or eliminating this excess paint, customers can experience greater transfer efficiency and cleaner applicators. The applicators new turbine is capable of speeds up to 100,000 rpm’s and can last over 2-3 times longer than previous model turbines.

FEATURES

Optimized Dual-Shaping Air

- Larger range of spray patterns

- Improved cleanliness

- Increased transfer efficiency

Improved Production Uptime

- Dual Purge capabilities reduces color change time

- New fluid nozzle design reduces solvent usage and cleaning time

- Quick disconnect tubing bundle removes applicator in less than two minutes

More Robust Components

- Longer turbine life

- New single-piece splash plate design

- Redesigned tubing bundle and cable connections

RMA 600 Series…..helping manufacturers finish first

Literature

-

RMA-660 Sales Literature 05-319-01

-

RMA-670 Sales Literature 05-320-01

-

RMA-680 Sales Literature 05-321-01

-

RMA-660 Robot Atomizer Service Manual

-

RMA-670 Robot Atomizers Service Manual

-

RMA-680 Robot Atomizers Service Manual

-

Turbine Rebuild Procedure SI-21-06

-

Cascade Assembly Service Instruction SI-22-02